HAGE LED

D e s i g n

Printed circuit board (PCB) light strip in an aluminium profiles covered with a half-round transparent satine or

white matt polycarbonate cover.

The advantage of our PCB light

strips over paper light strips is the quantity of current used in the installation and energy effficiency.

They are available in 8W (960 lm) and 4W (480 lm) variants. Compared with paper light strips, the 4W variant is twice

stronger for the same lenght, and the 8W vairant is four times stronger.

It can be used for interior and furniture design in a similar way as paper strips where stronger light is required.

Because they are connected in parallel, there can be an infinite number of PCB light strips connected together without

over heating and power losses as it happens with papaer light strips. They are also fully compatible with other 24VDC

appliances which can be connected together on the same power supply.

Each PCB light strip can be separately turned ON or OFF if the ON/OFF option is chosen. When this option is not used,

a simple, always-on variant can be used. It's possible to mix ON/OFF variants with always-on variants.

There is a wide range of colour available. It's also possible to mix PCB light strips of different colours in the

sequence that you want.

Available colours: Cold white, Warm white, red, blue, green, yellow,

amber, dark UV, agro light and other colours on demand. We can also offer mixed colours on the same board.

For example a mix of cold and warm white led diodes.

It's also possible to mix 4W segments with 8W segments to make some colours

or some areas shine stronger than others.

Another advantage is a much better temperature dissipation coeficient and a much better heat sinking capability.

It means that energy efficiency is much better. The board also includes verious electrical protection for better

reliability. We also offer the option to solder the wires directly or to use screwless, "wago" type terminals.

The disadvantage is that it requires installing wires parallel to the strips, but this is necessary

to efficiently carry a lot of current over the installation.

Without parallel wires, carrying a lot of current is not possible.

The design is also restricted to shapes with a minimum lenght of 50 cm per segment.

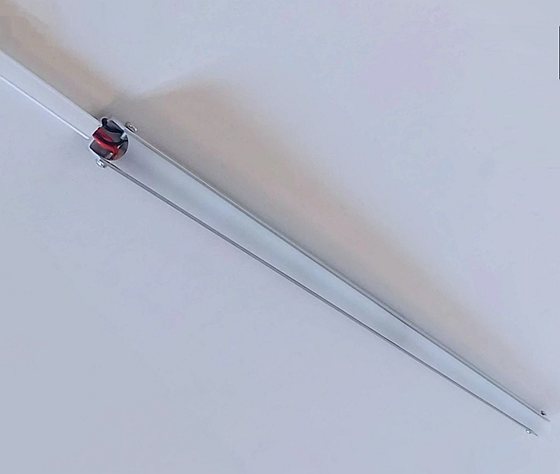

Our workshop can pre-assemble the PCB light strips on aluminium profiles, These profiles serve

as a cover to protect and hide the LED diodes and as a heatsink to difuse the temperature.

The pictures below show several samples of closed-case aluminium profiles with different PCB light strips inside.

The closed-case variant means that there is is plastic cover closing the aluminium profile. This solution is

recommended in direct light installations where the direct view on the LED diodes could be disturbing or when diffusion

is required for aesthetic.

Any "U" aluminium profile with an inner width larger than 19 mm can be used

with this type of cover. You can order U prfile with other sizes if they are

in stock at our suppliers. Customized profiles can be ordered only

in big quantities equivalent to 450Kg of aluminium profile weight.

Indoor use only.

Contact us:

+370 671 60006

ej@hageled.lt